The working principle of a pulsation dampener relies on a bladder and compressed inert gas inside it. When the pressure in the fluid system changes, the bladder expands or contracts accordingly, absorbing or releasing fluid to smooth out the pulsations in the system.

The damper contains an elastic bladder that is pre-filled with an inert gas at a certain pressure. The bladder is isolated from the fluid by a specific seal structure to ensure that the gas and liquid do not mix. When the pressure in the fluid system rises, the excess fluid is squeezed into the damper, forcing the bladder to compress, and the stored energy exists in the form of gas compression energy. When the system pressure drops, the gas in the bladder expands, pushing the fluid back into the system, thereby compensating for the pressure drop and effectively smoothing the pulsation. This process is dynamic and can be adjusted in real time according to changes in system pressure. Bladder Pulsation Dampener are particularly suitable for systems that handle relatively low pulsation frequencies, such as certain types of pumping systems. In extremely high-frequency pulsation environments, the response speed of the bladder may become a limiting factor.

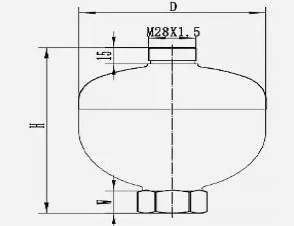

Diaphragm dampers use an elastic diaphragm as a separating medium to completely isolate the gas chamber from the fluid chamber. The diaphragm is usually made of high-strength, corrosion-resistant materials to adapt to high-pressure and corrosive fluid environments. Similar to the airbag type, the diaphragm damper also absorbs and releases the fluid through the reciprocating motion of the diaphragm to balance the system pressure. The difference is that the diaphragm type is more compact and may respond faster, especially suitable for applications with limited space or strict response time requirements. Since the gas is completely isolated from the fluid, the maintenance of the diaphragm damper is relatively simple, and only requires regular inspection of the integrity of the diaphragm. In addition, the pressure adjustment of the pre-charged gas is also more direct, which is convenient for optimization according to system requirements.

This type of damper does not rely on the movement of the airbag or diaphragm, but uses solid media to directly buffer and absorb the fluid. When the fluid passes through the damper, the solid medium absorbs the pulsation energy by virtue of its physical properties (such as pore structure, elastic deformation, etc.), converting it into heat energy or other forms of energy dissipation. The design without moving parts makes it extremely reliable and durable, and is particularly suitable for high-frequency pulsation, high-pressure or corrosive fluid environments, as well as occasions with extremely high cleanliness requirements.

Pulsation dampers can significantly improve the stability of fluid systems, reduce pipeline vibration, extend equipment life, and protect downstream sensitive components from pulsation shocks. In addition, they can also improve the volumetric efficiency of pumps and reduce energy consumption. The correct selection and use of pulsation dampers requires a deep understanding of the specific needs of the system, including pulsation frequency, amplitude, fluid properties, etc. Improper selection or operation may result in poor damping effect and even affect system performance.