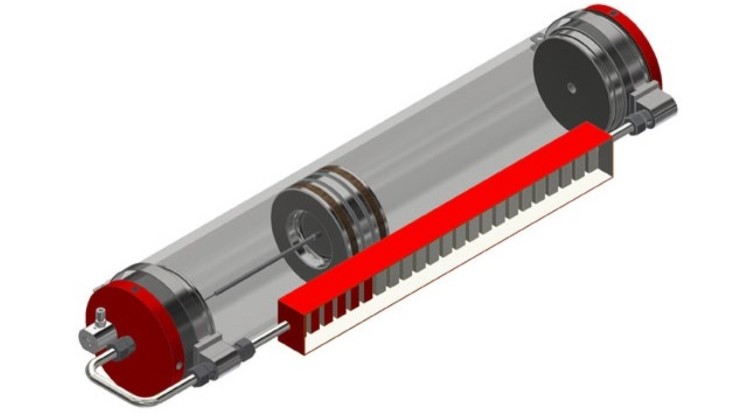

As an efficient energy storage and regulation device, the core of the Piston Accumulator is to use the difference in compressibility between gas and hydraulic oil to achieve dynamic balance and compensation of pressure. During the operation of the hydraulic system, if a certain part of the demand suddenly increases, causing the system pressure to rise rapidly, the Piston Accumulator will act as a "buffer pool". The hydraulic oil is pumped into the accumulator, compressing the nitrogen spring inside it, converting the excess hydraulic energy into the internal energy of the gas for storage. This process effectively alleviates the occurrence of system pressure peaks and prevents equipment damage or performance degradation caused by excessive pressure.

When the system pressure drops, such as when the load decreases or the pump output decreases, the nitrogen spring in the accumulator begins to expand due to the decrease in external pressure, pushing the piston forward, releasing the previously stored hydraulic energy, and replenishing it into the system to ensure that the system pressure remains within the set range. This automatic adjustment capability ensures the stable operation of the hydraulic system under different working conditions.

The role of the Piston Accumulator in shock absorption is mainly reflected in absorbing and dispersing the impact load and vibration energy in the hydraulic system to protect the system from damage. In hydraulic systems, especially those containing fast-acting or heavy-loaded components, such as the boom of a crane and the injection cylinder of an injection molding machine, instantaneous impact loads may cause sharp fluctuations in system pressure and even damage components. The Piston Accumulator can quickly absorb this impact energy through its internal elastic gas chamber and convert it into gas compression energy, effectively slowing down the flow rate and impact force of the hydraulic oil and protecting the system components.

In systems with continuous operation or periodic load changes, such as the walking mechanism of construction machinery and the propulsion system of ships, vibration is inevitable. Through its dynamic response capability, the Piston Accumulator can continuously adjust the flow of hydraulic oil, absorb and disperse vibration energy, reduce the vibration amplitude of the system, and improve the smoothness of operation.

These characteristics of the Piston Accumulator make it an important device in a variety of industrial applications, including ships used to stabilize the pressure fluctuations of the propulsion system and improve navigation stability. In heavy equipment such as excavators and loaders, it is used to absorb shocks, reduce vibrations, and protect hydraulic systems. In the steel and non-ferrous metal smelting process, it is used to adjust the pressure of the hydraulic system to ensure the continuity and stability of the production process. In flight control systems, it is used to quickly respond to pressure changes to ensure flight safety.